High Quality Direct to Fabric (DTF) transfers are transforming bulk shirt production by offering vibrant, durable printing on diverse fabrics like cotton and polyester. This technology involves applying a thin film of ink directly onto fabric, activated under heat and pressure for seamless integration. Cotton and polyester, with their color absorption properties and unique traits, are ideal DTF choices. Optimizing techniques, including selecting the right printer, pre-treating fabrics, and using high-quality transfer films, ensures superior results. High Quality DTF Transfers cater to businesses creating custom apparel or merchandise at scale.

“Discover the art of high-quality DTF (Direct-to-Fabric) transfers, an innovative printing technique revolutionizing textile design. This article explores the versatility of cotton and polyester fabrics as ideal canvases for DTF printing. From understanding the process to mastering techniques, we guide you through achieving exceptional results. Learn how to navigate the materials, inks, and methods to create vibrant, long-lasting designs on both natural and synthetic fibers, ensuring your DTF transfers stand out.”

- Understanding DTF Transfers: A Comprehensive Overview

- The Versatility of Cotton and Polyester Fabrics for DTF Printing

- Ensuring Optimal Results: Techniques for High-Quality DTF Transfers on Cotton and Polyester

Understanding DTF Transfers: A Comprehensive Overview

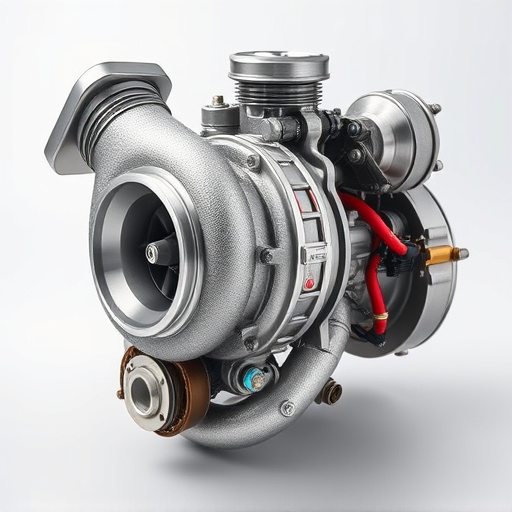

DTF (Direct to Fabric) transfers are a cutting-edge printing technology that allows for high-quality designs on various fabrics, including cotton and polyester. This method involves applying a thin film of ink directly onto the fabric’s surface, creating a vibrant and durable print. High-quality DTF transfers offer an innovative solution for bulk shirt production, ensuring consistent and precise results.

The process begins with preparing the dtf transfer film, which is designed to adhere temporarily to the fabric. This film carries the design or image that needs to be printed. During the printing stage, heat and pressure are applied to activate the ink on the film, transferring it onto the target fabric. The result is a crisp, clear image that becomes an integral part of the fabric, suitable for both decorative and functional purposes. With advancements in technology, DTF transfers have become accessible and efficient for businesses looking to create custom apparel or merchandise at scale.

The Versatility of Cotton and Polyester Fabrics for DTF Printing

Cotton and polyester fabrics are the most versatile choices for Direct-to-Fabric (DTF) printing, offering a wide range of benefits for both designers and manufacturers. DTF for apparel has gained significant traction due to its ability to print high-quality designs on various textile materials. These fabrics provide excellent absorption properties, ensuring vibrant and long-lasting colors in the final product. Polyester, known for its durability and wrinkle-resistant nature, is particularly suitable for activewear and outdoor garments, while cotton’s breathability makes it a preferred option for everyday clothing items like t-shirts and hoodies.

Understanding the unique characteristics of each fabric allows printers to optimize their DTF techniques accordingly. For instance, polyester’s smooth surface facilitates precise printing, resulting in crisp text and intricate graphics. Cotton, with its slightly textured feel, may require specific settings to achieve sharp details without any print distortion. With the best DTF printer and high-quality transfers, creators can produce stunning designs that truly bring their artistic vision to life across both cotton and polyester fabrics.

Ensuring Optimal Results: Techniques for High-Quality DTF Transfers on Cotton and Polyester

Achieving exceptional results with High Quality DTF Transfers on cotton and polyester fabrics requires a meticulous approach. First, selecting the right direct to film (DTF) printer is paramount; these specialized printers ensure precise color reproduction and crisp detail transfer. Next, pre-treating the fabric is essential—a simple wash and dry cycle can prepare both cotton and polyester surfaces for optimal adhesion.

For Cotton: Consider a mild detergent and cool water wash, followed by air drying to prevent shrinkage or distortion. For Polyester: A quick steam press at low temperature can activate the fabric’s fibers, enhancing print receptivity without causing damage. Additionally, using high-quality transfer films designed for DTF printing ensures smooth application and easy removal, leaving a vibrant, long-lasting design on the fabric surface.

High-quality DTF (Direct to Fabric) transfers have revolutionized printing on cotton and polyester fabrics, offering exceptional versatility and results. By mastering techniques such as preparing surfaces, choosing appropriate inks, and optimizing press settings, creators can achieve vibrant, long-lasting designs. Whether for apparel, home decor, or promotional items, high-quality DTF transfers elevate the final product, ensuring it stands out in today’s market.